Boilers require annual professional maintenance at minimum, ideally in early fall before heating season. Systems over 15 years old or those with water quality issues benefit from bi-annual service. The closed-loop water system accumulates contaminants requiring regular attention. Between professional visits, monthly pressure checks help identify developing issues early.

Comprehensive boiler maintenance includes water quality testing and treatment, combustion analysis and adjustment, safety control verification, circulator pump service, expansion tank testing, zone valve operation checks, pressure optimization, efficiency testing, and complete system inspection. This goes far beyond basic furnace maintenance, addressing the unique needs of hydronic systems.

Water treatment prevents scale formation, corrosion, and efficiency loss. Parker's water contains minerals that accumulate in boilers, reducing heat transfer and causing component damage. Proper treatment can double boiler lifespan while maintaining efficiency. Untreated systems often fail in 15-20 years versus 30-50 years for treated systems.

Yes! Professional maintenance typically reduces heating costs 10-20% through optimized combustion, clean heat transfer surfaces, proper water temperature settings, and efficient circulation. Scale buildup alone can increase fuel consumption 10%. Combined with prevented repairs, maintenance pays for itself while ensuring comfort.

Skipping maintenance leads to scale buildup, corrosion acceleration, efficiency losses of 20-30%, increased breakdown risk, potential safety hazards, and shortened equipment life. Boilers are pressure vessels requiring safety verification. The closed water system accumulates problems without regular service. Neglect risks both safety and expensive failures.

Absolutely! First-year maintenance is crucial for removing installation debris, establishing proper water chemistry, verifying correct operation, and validating warranties. New systems often need adjustment after break-in. Skipping early maintenance can void warranties and miss problems covered under installation guarantees.

Comprehensive boiler maintenance typically takes 90-120 minutes, longer than furnace service due to water system requirements. First-time maintenance on neglected systems may take longer. We perform thorough service including water testing, combustion analysis, and complete inspection. Quality maintenance ensures safe, efficient operation.

Boiler maintenance includes water chemistry management, hydronic component service, pressure system checks, and circulation optimization absent in furnace service. Boilers require understanding of water treatment, expansion control, and zone systems. The specialized knowledge needed is why choosing boiler experts matters for proper maintenance.

Yes! Regular maintenance identifies potential leak sources early through pressure testing, visual inspection, and water quality management. Proper water treatment prevents corrosion leading to leaks. We catch minor seepage before major failures. Maintained systems experience 80% fewer leaks than neglected units.

Never add chemicals without professional guidance. Wrong chemicals or amounts can cause severe corrosion or scaling. We test water quality and add appropriate treatment during maintenance. DIY chemical addition risks system damage and safety hazards. Professional water treatment protects your investment properly.

Signs include unusual noises, pressure fluctuations, uneven heating, increased fuel bills, visible leaks or corrosion, frequent air in radiators, or simply annual service due. Don't wait for problems—preventive maintenance costs far less than repairs. If you can't remember last service, schedule immediately.

We maintain all major boiler brands including Weil-McLain, Burnham, Buderus, Viessmann, Lochinvar, Peerless, Crown, Columbia, and others. Our NATE certified technicians receive ongoing training on various brands. Whether your boiler is new or decades old, we have the expertise for proper maintenance.

Yes! Fall maintenance ensures your boiler is ready before heating demands begin. You have time to address any issues found, water treatment is most effective before heating season, and technician availability is better. However, maintenance anytime is better than none. We provide year-round service.

We provide comprehensive documentation including water quality test results, combustion efficiency readings, safety check confirmations, component condition assessments, service performed checklist, and recommendations. This documentation supports warranty claims, tracks system health, and provides maintenance history for your records.

Absolutely! Regular professional maintenance can extend boiler life from 15-20 years (neglected) to 30-50 years (maintained). Proper water treatment prevents corrosion, cleaning maintains efficiency, and component service prevents failures. Maintenance provides exceptional value.

Yes! Our boiler maintenance contracts ensure annual service without forgetting, include water treatment, provide repair discounts, and offer priority service. Contracts are customized for boiler systems with options for various needs and budgets. This systematic approach maximizes boiler life while minimizing costs.

If we discover issues during maintenance, we document findings, explain implications clearly, provide repair options and estimates, and prioritize safety concerns. There's never pressure for immediate repairs unless safety is compromised. Maintenance plan members receive 15-20% repair discounts. We help you make informed decisions.

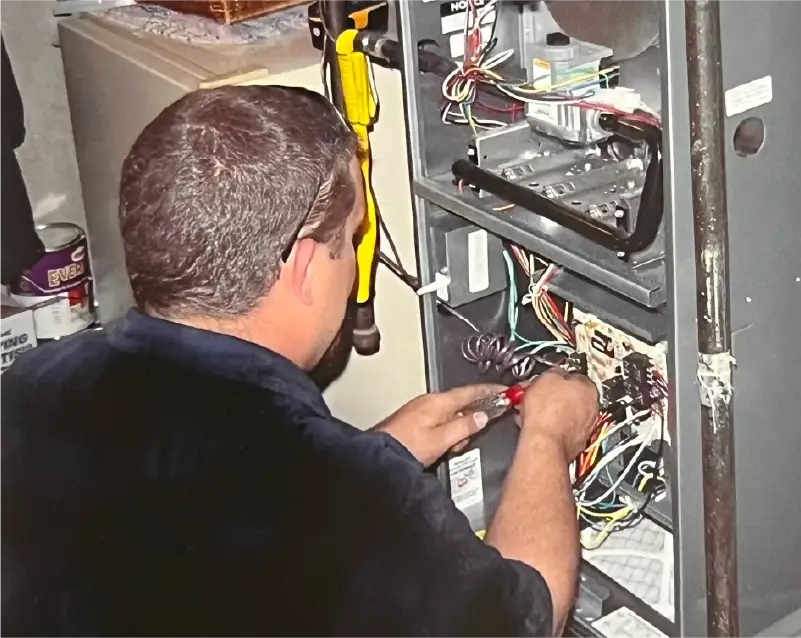

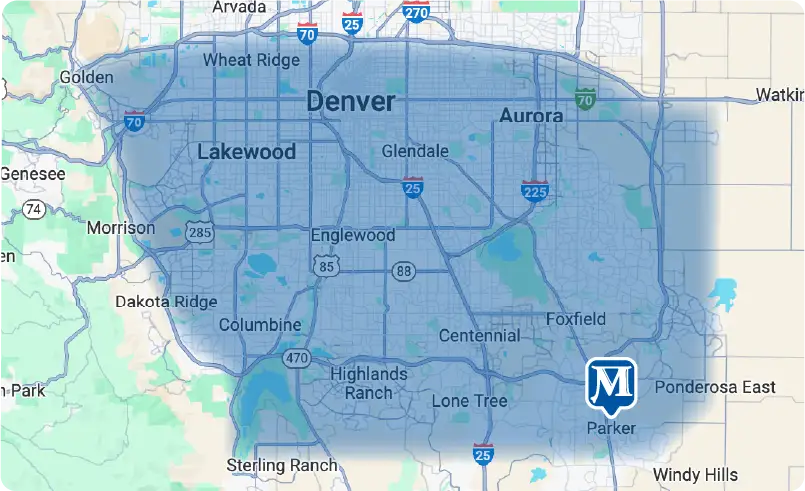

Since 1993, we've developed specialized boiler expertise many companies lack. Our NATE certified technicians understand hydronic systems thoroughly including water chemistry, pressure dynamics, and circulation requirements. With veterans on staff, we bring meticulous attention to detail. We perform comprehensive maintenance that actually improves performance and longevity.